Our Products

Main Features:

1. The whole EU streamlined design, heat treatment rack, high rigidity worktable, optional mechanical crowning device, to achieve precision bending .

2. Hydraulic synchronous control and Estun NC programmable logic controller ensure accurate repeatability and easy use .

3. Integrated hydraulic system (Bosch Rexroth Germany/First USA) allows automatic switch to slow bends in a quick way.

4. X-axis and Y-axis realize accurate positioning function by frequency converter through NC E21 system programming control.

5. Cutting-edge frequency response hydraulic control technology, more stable machine tools, more reliable operation .

6. The best ratio of parameters, optimal core configuration ensure stable performance, more convenient operation .

7. WC67K standard single-axis back gauge system and single-axis bending angle system, you can choose to add the V-axis crowning function, and select the appropriate mold to bend complex shape workpieces easily .

Main Configuration:

- Estun E21 NC control system

- Y-axis and X-axis system control adjustment

- Delta frequency converter controls the positioning of X axis and Y axis

- Using SHAC ball screw and light bar to ensure the accuracy of 0 . 05mm .

- Clip-on quick clampings

- Front holder support

- Germany Bosch Rexroth hydraulic valve block

- Germany EMB oil tube connector

- Germany Siemens main motor

- France Schneider Electric

- Hydraulic and electrical overload protection

- Top and bottom dies (86°, R0 . 6mm, material: 42CrMo)

MACHINE BLOCK:

The press brake features a rigid frame for min deflection under the load. The frame steels are German origin and designed using SOLIDWORKS 3D programming and made with quality steel Improved Q235 using the latest technology.

Features:

• The machine welding is made by welding aparatus and welding robots.

• After the welding, we make stress relief process by vibration system.

• After the stress relief process machine frame goes to CNC 5 axes machining centers for accuracy.

• All reference surfaces and connection holes are machined.

• By all these processes machine frame sensitivity is protected for a long life time.

PRO S PRESS BRAKE CYLINDERS:

To allow tilting of the ram without damage, because we use spherical connections. This type of connection also allows peak forces to be absorbed gently.

Advantages:

- High-Speed Free Fall

- High Bending Speed

- High Return Speed

- Very low noise level.

- Free-fall bending & return speeds of EURO PRO S press brakes series makes is the best choice to meet demands in today’s competitive markets.

- PRO S series offer twice as fast production capacity compared to conventional NC press brakes.

SPEED GRIP SYSTEM:

The speed grip system reduces the time spent changing tools by 80% compared with traditional systems.

Advantage:

• Vertical tool exchange

• Safety guard

• Includes selectable intermediates

Features:

● Backgauge control

● Control the common motor or inverter

● Intelligent positioning

● Holding pressure unloading time setting

● Workpiece counting

● 40 programs stored, 25 steps per program

● Unilateral positioning

● Concession function

● One-key backup / restore

● mm / inch

● Chinese / English

MANUAL MECHANICAL CROWNING SYSTEM (Optional):

The system allows the user to manually control the deformation of the beam during bending. Therefore, the angle remains constant throughout the length of the board.

Advantage: The convexity system is controlled by hand to execute the convexity and make the part in a uniform bending angle at any given point.

We stand by your side, no matter your needs

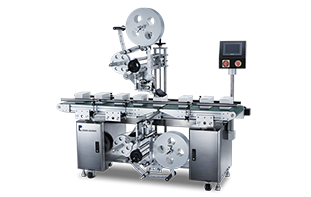

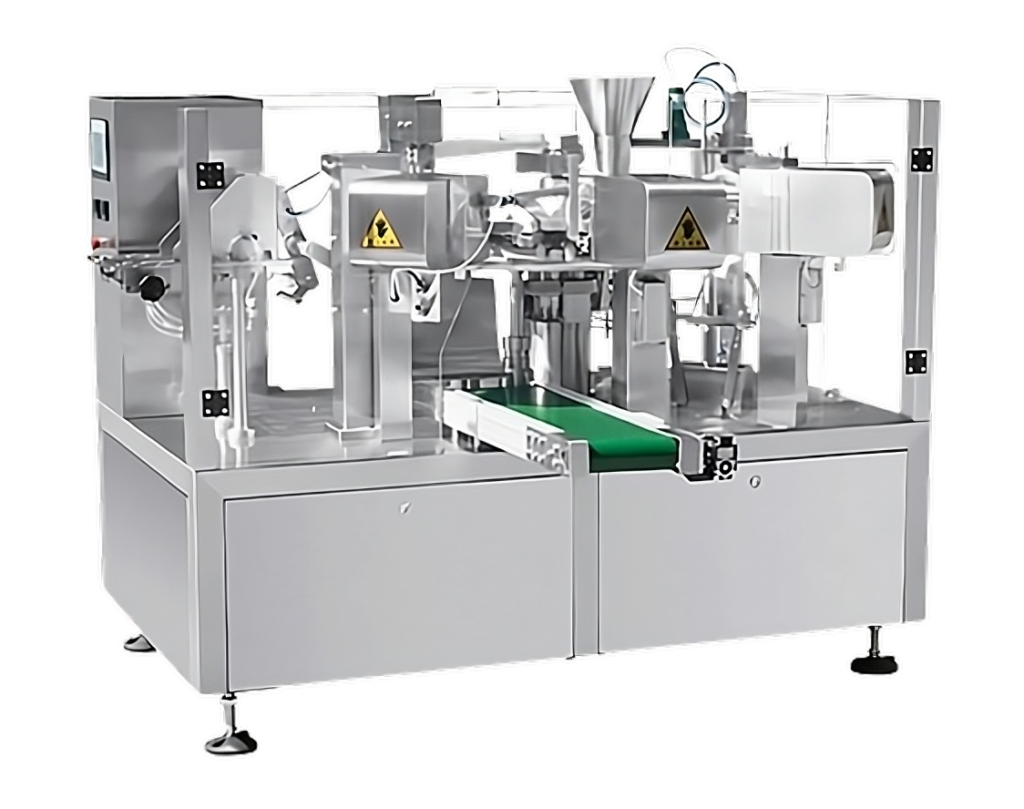

VYTE Industrial Solutions operates in the field of industrial production, packaging, and labeling machinery, with bottling, filling, screwing, capping, vacuum, wrapping, sealing, and labeling machines. It aims at small and large production lines in the food, pharmaceutical, cosmetic, and chemical industries.