Our Products

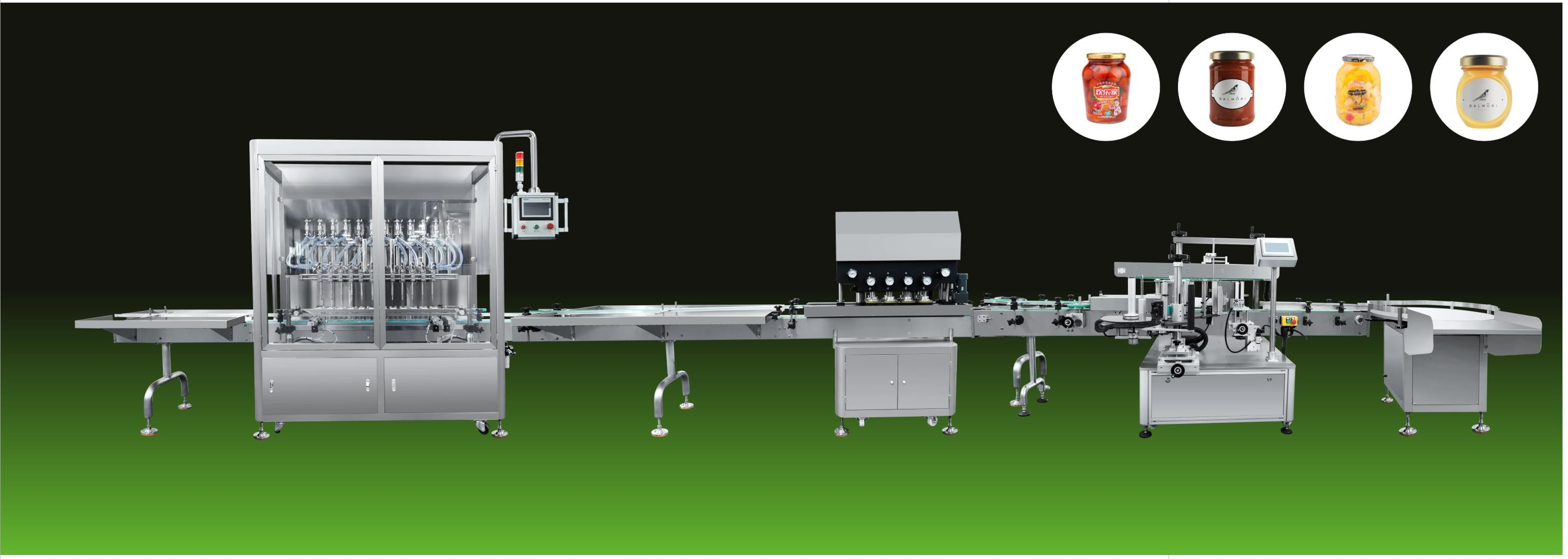

8-head servo piston filling machine

♦ → Number of filling heads: 8

♦ → Filling range: 100ml-1000ml

♦ → Filling form: servo piston

♦ → Filling speed: 2400 bottles/hour (calculated by 100ml)

♦ → Filling accuracy: ±1%

♦ → Material: The filling frame is made of 304# stainless steel

♦ → Program control: PLC+ touch screen

♦ → Materials of filling nozzle and material tank contacting liquid: 316# stainless steel, polytetrafluoroethylene

♦ → Air pressure: 0.6-0.8Mpa

♦ → Conveyor belt: 82.6mm wide pom chain belt, ground height 800mm±25mm

♦ → Conveying motor: 750W AC motor

♦ → Power: 3.5KW/220V

♦ → Trough capacity: 150L (with level switch)

♦ → Protection device: alarm for when the storage tank is short of liquid and for shutdown

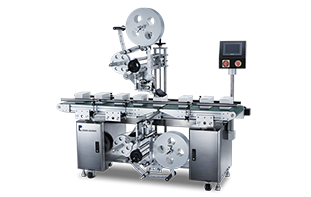

Flat bottle double side round bottle labeling machine

♦ → Applicable product range: According to samples provided by customers

♦ → Applicable label range: according to the sample provided by the customer (non-transparent label)

♦ → Labeling position: flat bottle with double sides, round bottle with single and double labels

♦ → Labeling accuracy: plane ±1mm, curved surface ±1/5mm (not including product shape error)

♦ → Production capacity: 0-20m/min

♦ → Voltage: 220V/50Hz

♦ → Power: about 2KW

♦ → Program control: Siemens PLC+ touch screen man-machine interface

♦ → Photoelectricity for bottle testing: easy for Germans LEUZE

♦ → Motor for standard delivery: Schneider, France

♦ → Inverter: Siemens, Germany

♦ → Conveyor belt: 82mm wide POMchain belt, ground height 750mm ±25mm

♦ → Conveyor belt motor: 370W frequency conversion motor

♦ → Frame material: stainless steel + aluminum profile

♦ → Applicable paper roll: inner diameter Φ76mm, maximum outer diameter Φ300MM

♦ → Air pressure: 0.6~0.8MPa

We stand by your side, no matter your needs

VYTE Industrial Solutions operates in the field of industrial production, packaging, and labeling machinery, with bottling, filling, screwing, capping, vacuum, wrapping, sealing, and labeling machines. It aims at small and large production lines in the food, pharmaceutical, cosmetic, and chemical industries.