Our Products

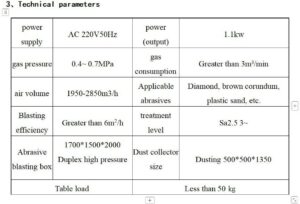

High-pressure box type sand blasting machine is a new type of recycling sand blasting machine, which adopts the working principle of injection and suction type, is easy to operate, does not pollute the environment when working, and the abrasive material is automatically recycled, separated and screened.

It is widely used for surface descaling and surface strengthening of small metal workpieces in the industries of machinery, ships, bridges, railroads, petroleum pipelines, boilers and harbor construction, etc.; as well as surface carving and spraying decorative treatment of leather, clothes, glass and stone, etc.

- 880L Cabinet Sandblaster with paralleled working position

- Paralleled cabinet suit for especially long work piece

- LED light

- Could use two different media to blast on separated funnel design.

- Working space: 2000*680*650mm

- Sanding load: 52L (each funnel 26L)

Because of the difference in material density, the data of loading amount is for reference.

Operation steps

1、Preparation and inspection before use

The appearance of the machine should be intact, and all parts should be firmly connected without damage. All kinds of pipelines should be free of cracks, fractures and aging phenomena, and no leakage.

2、Power on and ventilate

Turn on the power, open the power switch (dust removal fan start). Turn on the power, open the power switch (the dust blower starts. The lighting of the working warehouse starts).

Open the gas source, adjust the regulator to the maximum (regulator has an arrow, observe the machine front air inlet pressure).

Depress the footswitch (a large amount of gas is discharged from the spray gun). Open the door to pour abrasive (40-100 mesh)

3、Work

Put the workpiece into the sand blasting box on the worktable and close the door. The operator stands in front of the sand blasting box, reaches into the sand blasting gloves with both hands, holds the workpiece and the spray gun, and steps on the foot switch to start the sand blasting operation.

4、Stop

Release the foot switch, stop sand blasting (clean up the workpiece with blowing gun) and wait for the dust to be sucked away completely.

Open the box door and take out the workpiece. Turn off the power switch, open the dust valve (continuous switch 5 to 6 times) and then open the back of the machine to remove the dust baffle to release the dust.

- Gun nozzle: 8mm boron carbide

- Sight glass (ordinary glass)

- Rubber gloves

We stand by your side, no matter your needs

VYTE Industrial Solutions operates in the field of industrial production, packaging, and labeling machinery, with bottling, filling, screwing, capping, vacuum, wrapping, sealing, and labeling machines. It aims at small and large production lines in the food, pharmaceutical, cosmetic, and chemical industries.