Our Products

Main Features:

1. Streamlined design originated from EU, main structure consists of rack, cutter holder, oil cylinder, hydraulic controller, backgauge and others. Finite-element analysis of main parts, Welding parts uses tempering, vibration and other processing methods to eliminate stress ensuring the structural strength and rigidity of each component;

2. Cutter holder use three-point support rolling guide rail, reducing the friction to the greatest extent, and realizing seamless rolling during cutter holder moving.

3. Left-most front holder configured with verticality regulator and front positioning device, easy operation and high efficiency;

4. Simple and effective blade adjusting mechanism rearranges blade clearance by CNC system, improving the cutting quality.

5. Fine ball screw and polished rod structure, using good-performance frequency converter positions X axis to ensure accuracy, unique designed timing transmission mechanism, stable and reliable.

6. Light and shadow line is conductive to manual scribing for cutting; stable and reliable hydraulic transmission; integrated hydraulic system is able to significantly alleviate problems causing by hydraulic fluid leakage.

7. Made by high-quality alloy tool steel capable enough to against impact load and high wear resistance when cutting;

8. With reference to ergonomic design, easy operation with NC system surface, improving the operation precision and comfortability; rolling ball workbench to reduce friction and prevent work piece surface from scratching; unique and practical safety guard, line with safety specifications, protect the personal safety; exquisite design, petty work piece can be done easily by hand.

Machine Block:

Impressive cutting technology: the guided shear technology is based on the straight vertical movement of the cutter bar. It is a simple and therefore extremely economical solution for straight cuts.

The range of tasks is very wide, since the cutting angle and kerf are set individually and automatically.

Features:

• The machine welding is made by welding aparatus and welding robots.

• After the welding, we make stress relief process by vibration system.

• After the stress relief process machine frame goes to CNC 5 axes machining centers for accuracy.

• All reference surfaces and connection holesare machined.

• By all this processes machine frame sensivity is protected for a long life time.

We stand by your side, no matter your needs

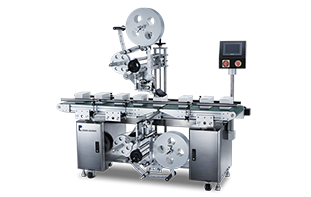

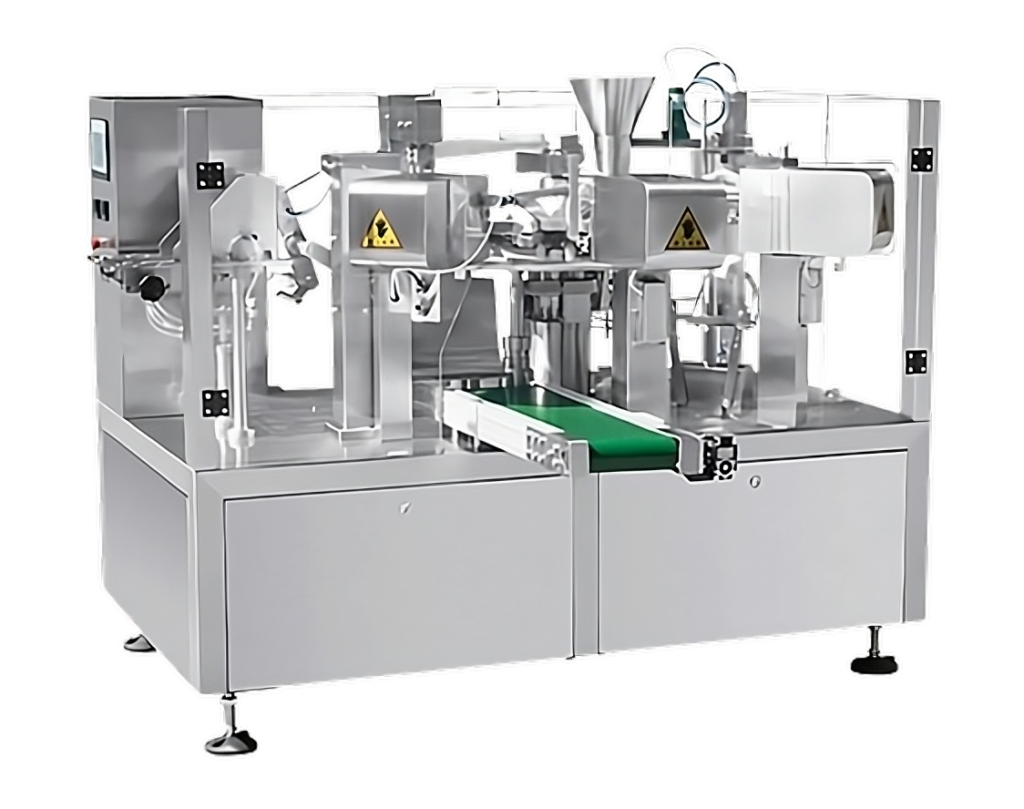

VYTE Industrial Solutions operates in the field of industrial production, packaging, and labeling machinery, with bottling, filling, screwing, capping, vacuum, wrapping, sealing, and labeling machines. It aims at small and large production lines in the food, pharmaceutical, cosmetic, and chemical industries.