Our Products

Designed for limited space installation (compact dimension). Suitable for small and medium size packages, online metal detection and weighing.

FEATURES

- Multi-Frequency and Dual-System detection technology

- Multiple detection mode automatic or manual setup

- In system Oscilloscope

- Equipped with dynamic loadcell and high speed DSP

- Automatic product Guide, Zero Tracking and Trend Follow Up

- Metal Detector / Check Weigher can be turned on/off individually

- Metric/Imperial and Normal/EU regulation shift

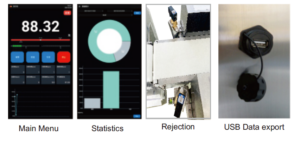

- 13 inches touch screen with android system which support multiple languages

- Points configurable real-time weight curve display

- Large system memory which supports long term recording, fast seeking and recalling

- Supports graphic based production statistic and analysis

- Equipped with BLDC motor which is performing high speed and low dither

- Records could be export to USB drive (CSV format)

- Data export by ethernet port

- Various rejectors optional

- Rejection feedback, air pressure monitor, fill up detection and locked bin optional

- SUS304 frame with Tool Free conveyor removal

SPECIFICATIONS

Model | MDC-Combo II 300 | MDC-Combo II 400 |

MD principle | Balanced Coil | |

Window Size(L*H) | 300*120mm | 400*150mm |

Max. Sensitivity | Fe0.6/SUS1.2mm | Fe0.8/SUS1.5mm |

Range (g) | 6~2000 (5000 optional) | |

Accuracy (g) | 0.3 | 1 |

Platform Size (L*W) | 440*200mm | 440*300mm |

Belt Width | 200mm | 300mm |

Max. Speed | 180ppm | |

Rated Power | 320w | |

Effective Work Size (L*W) | 390*200mm | 390*300mm |

Resolution | 0.01g | 0.01g |

Loadcell type | Strain-Gauge | |

Belt Speed | 22~76m/min | |

Rejector | Air blast/Pusher/Flap/Drop Off | |

Power Supply | AC100~240V,50~60Hz, Single Phase | |

Accessories | Windshield Signal tower, USB, RS-232, Ethernet | |

※Accuracy and speed depends on product status, form and tandem space.

We stand by your side, no matter your needs

VYTE Industrial Solutions operates in the field of industrial production, packaging, and labeling machinery, with bottling, filling, screwing, capping, vacuum, wrapping, sealing, and labeling machines. It aims at small and large production lines in the food, pharmaceutical, cosmetic, and chemical industries.