Our Products

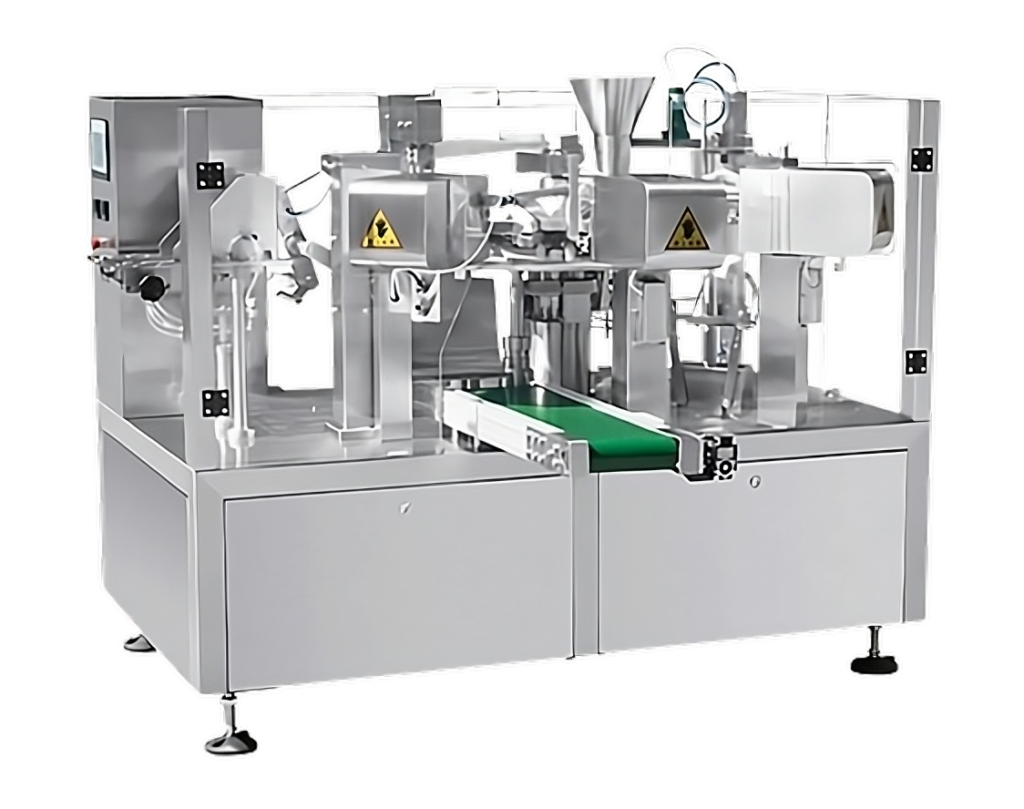

Machine features

♦ → The machine adopts linear filling, which is suitable for various high/low viscosity materials

♦ → Automatic air washing, filling, plugging, capping, container discharge and automatic refilling

♦ → Straight-line operation, the ficture can be used automatically and circularly

♦ → The clamps are adjustable, and different bottle types can be filled by simply adjusting the clamps to change the bottle type

♦ → Servo motor combined with rotary valve, piston quantitative filling, convenient control, simple adjustment and high filling accuracy

♦ → Screw cap servo lift, manipulator clapms the cap, the cap size is adjustable, the cap screw torque is adjustable, and the cap is not damaged

♦ → The manipulator automatically discharges the finished product, which is convenient and reliable

♦ → Combined filling structure, accurate filling volume, easy to disassemble and clean

♦ → The volume adjustment is simple, the operation is convenient and safe.

♦ → Equipped with movable wheels, ease to move

♦ → The whole machine is made of sanitary stainless steel, clean and hygenic.

Technical parameters

♦ → Number of filling heads: 4

♦ → Filling range: 10ml-100ml

♦ → Filling form: Servo piston multi-head filling

♦ → Filling speed: 2000 bottles/hour (calculated by 30ml)

♦ → Filling accuracy: ±1%

♦ → Material: The filling frame is made of 304# stainless steel

♦ → Program control: PLC+ touch screen

♦ → Filling nozzles and material tanks and other liquid contact parts

♦ → #304 Stainless steel, PTFE

♦ → Air pressure: 0.6-0.8MPa

We stand by your side, no matter your needs

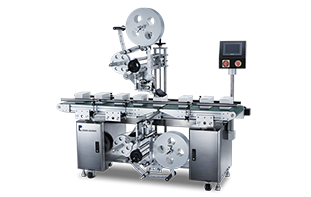

VYTE Industrial Solutions operates in the field of industrial production, packaging, and labeling machinery, with bottling, filling, screwing, capping, vacuum, wrapping, sealing, and labeling machines. It aims at small and large production lines in the food, pharmaceutical, cosmetic, and chemical industries.